Intelligent & Comprehensive Fault Diagnosis

The intelligent fault diagnosis feature of e-MCM makes it very simple to use by the maintenance personnel.

Rather than overwhelming the end-user with raw signals and data, e-MCM provides processed data results in an actionable form.

Utilizing a database of over 10 million fault signatures, e-MCM detects and diagnoses issues up to 6 months in advance, ensuring prompt intervention.

- Mechanical Faults: Loose foundation, unbalance & misalignment, belt, gearbox, bearing, impeller, fan blade and more..

- Electrical Faults: Stator, rotor, winding isolation, power quality ,power circuit and more..

- Process Issues: Cavitation, clogging, overload, low efficiency, plugged filters, flow turbulence and more..

Pump Performance Monitoring

- Smart Flow & Pressure Estimation:Utilizes advanced algorithms to accurately estimate flow and pressure using only motor power data—no external sensors required.

- External Sensor Integration:Seamlessly integrates with external flow and pressure sensors if available, enhancing monitoring precision and data depth.

- Duty Point Tracking:Continuously monitors the pump’s duty point, highlighting deviations from the Best Efficiency Point (BEP) to maintain optimal performance.

- Automatic Condition Diagnosis:Automatically diagnoses pump operating conditions, delivering specific insights that enable operators to take timely and informed actions.

- Energy Efficiency Optimization:Identifies inefficiencies and optimizes pump operations to enhance energy usage, reducing overall operational costs and improving sustainability.

Energy Efficiency & Cost Analysis

Energy usage is one of the largest operating expenses in any facility with extensive motor-driven systems.

e-MCM’s Efficiency & Cost Analysis module transforms raw current and voltage data into actionable financial metrics:

- Inefficiency Detection: Identify inefficiencies caused by faults, mechanical wear, or process issues.

- Real-Time Energy Savings Metrics: Provide real-time energy savings metrics, helping reduce operational costs.

- Energy Consumption Optimization: Optimize motor and pump operations for minimal energy consumption. By addressing inefficiencies, e-MCM not only reduces costs but also contributes to sustainability goals.

- Optimal Motor Sizing & Efficiency Recommendations: Utilizing its extensive database, e-MCM suggests the ideal motor size and efficiency class for your specific application, providing the essential data needed to accurately calculate ROI..

AI-Driven Digital Twin

- Self-Learning Phase: Utilizes advanced system identification algorithms to build a robust mathematical model, capturing normal machine behavior across various load and speed conditions.

- Real-Time Data Comparison: Continuously measures motor voltages and currents, matching them against the digital twin to detect even subtle deviations from normal operation.

- Minimized False Alarms:Recognizes different operating states—like varying loads or speeds—to avoid unnecessary alerts while maintaining tight fault detection accuracy.

- Full Machine Train Coverage: Identifies and diagnoses issues not just in the motor, but also in the drive train and connected equipment, using the motor itself as a sensor.

- Intuitive Traffic Light Interface: Provides clear indications of fault severity (green, orange, red), alongside estimated time-to-failure and recommended corrective actions.

Simplified Installation & Integration

A key benefit of e-MCM is its ease of installation and integration. Because it relies solely on motor current and voltage readings, e-MCM:

- Requires Minimal Hardware: No invasive sensor mounting or modifications to existing machinery are necessary.

- No Size or Voltage Limitations: e-MCM is compatible with all motor-driven systems, regardless of size or voltage, making it ideal for any application.

- Seamless Integration with Existing Systems: Effortlessly connects to SCADA, DCS, and other plant control systems using standard industrial communication protocols.

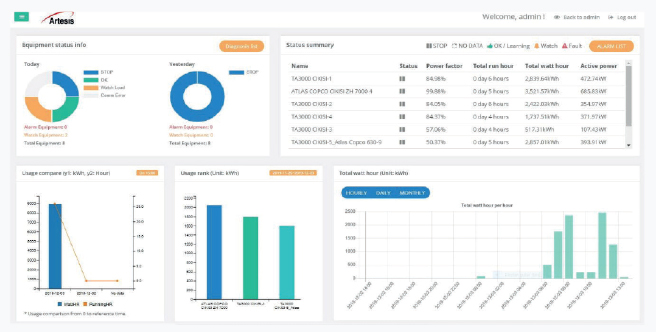

- Features a User-Friendly Interface: Delivers intuitive dashboards for real-time monitoring, fault alarms, and trending.